11 Mar Glove Risks: Puncture

It is often assumed that a glove with high cut protection is also going to be good at protecting against punctures. Even though this assumption very often proves correct, it is possible to have a glove that is good at cut protection that isn’t so protective of punctures. Why not be sure?

Who needs to worry about puncture injuries? Anyone who handles material that contains sharp, pointy objects like nails, thorns, or metal burrs. Glass workers need cut resistance when handling the edge of a pane of glass, but that same pane can shatter, and the shards become puncture hazards.

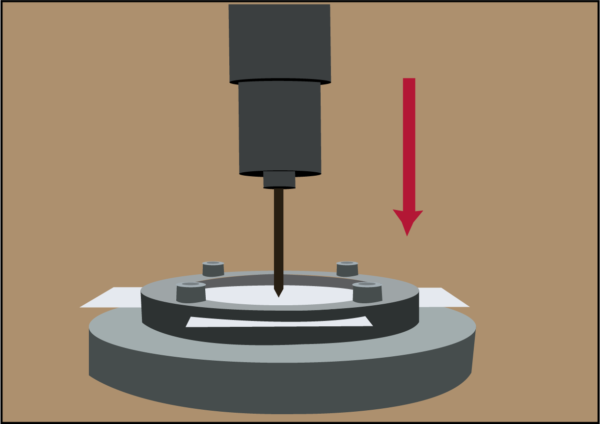

The ANSI test for puncture takes a swatch from the palm of the glove and sandwiches it between two metal plates with a hole in the center of the plates. A stylus about the width of a pencil point attempts to push through the glove material exposed by that hole.

The force required to penetrate the glove material is the basis of the rating.

Force (in Newtons) required to penetrate material:

| 0 | 1 | 2 | 3 | 4 | 5 |

| < 10 | ≥ 10 | ≥ 20 | ≥ 60 | ≥ 100 | ≥ 150 |

As with the other ratings, they are based on samples of the palm of the glove. Anywhere the construction of the glove is different than the palm, the puncture rating is not necessarily the same.

Click HERE to view a video version of this post.

No Comments