18 Jan May you never need to use Chris’ Eye Magnet Loop!

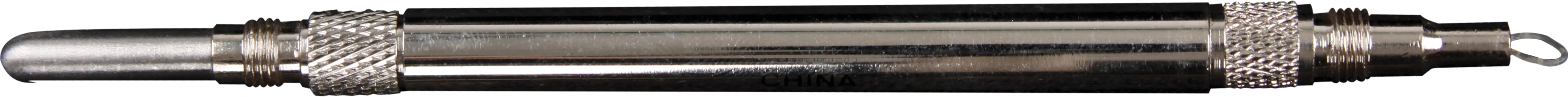

We have an item in our catalog we call Chris’ Eye Magnet Loop. It looks like an object that would be right at home alongside all those other tools you see neatly lined up on a tray next to a dentist’s chair, but it is not for teeth. It has a closed wire loop on one end, and the other end is strongly magnetic. We named it after the guy who first requested a tool that could remove metal chips and other stuff from his workers’ eyes.

We think every safety manager should own one of these tools, if for no other reason than to brandish it during training sessions. All you have to do is describe how each end of the tool is employed to relieve a patient of a splinter in the eye, and enthusiasm for wearing safety eyeglasses is bound to spike!

OSHA Rules

When it comes to eye protection, there are a lot of guidelines, but few rules, unless you have a work environment that could expose you to a chemical spill. OSHA’s 29 CFR 1910.151 contains the following dictum: “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.” If you have a work environment that you believe meets that description, the regulation has very specific requirements in terms of how far away the eye wash/shower can be located, restrictions of obstacles in the path between work area and wash station, temperature of wash water, length of time the wash must be capable of delivering an uninterrupted stream of water, etc. Work locations that fit the description would do well to make sure that all the requirements in this regulation are met. An eyewash station that meets the requirement is typically built into the physical plant of the facility, but there are self-contained portable versions available from your supplier as well.

For working environments that do not include the imminent risk of corrosive material spills, OSHA expects employers to be familiar with the ANSI guidelines and to implement a proactive policy as common sense would dictate. For many facilities, that would include placement of emergency eye wash bottles in strategic areas and a mandate to wear safety glasses, goggles and/or face shields as the situation requires.

The Bottle Vs. The Eye Wash Sink

An emergency eye wash bottle differs from a 29 CFR 1910.151 station in that it will not provide a continuous 15-minute stream of eye wash. These bottles are typically between 8 and 32 ounces and are often sold in a wall-mountable “station” with emergency instructions posted on the fixture. They are sterile, single-use vessels with expiration dates printed on them. The user grabs the nearest bottle from its mount, unscrews the seal and squeezes the inverted bottle while aiming the stream at the affected eye. In addition to the bottles ready for use mounted on walls, it is advisable to keep spares on hand to replace the bottles that get used or exceed the date.

There is also a product popular with first responders that meets the needs of vehicle-based personnel. It’s called Bio Med Wash®, and it contains lab-grade water packaged in a pressurized aerosol can that dispenses the sterile solution in a low-pressure stream when you depress the trigger. It has a 4-year shelf life and comes in single-use cans of various sizes.

One of the biggest challenges with eye wash products in a mobile context is temperature control. The prescribed temperature range for eye wash is 60° to 100°F. Products should be kept from being stored where they will freeze or get too hot. Unless the vehicle is kept overnight in a temperature-controlled shelter, it will be necessary to move your safety kit to a temperate location when not in use. There are self-contained 29 CFR 1910.151-compliant eye wash stations that are designed to provide a 15-minute stream of heated water in a portable format as well.

UV Radiation and Safety Glasses

It should go without saying that the first step in protecting worker’s eyes is safety glasses, face shields or goggles. With rare exception, ANSI rated safety glasses are constructed of polycarbonate, which blocks 99.9 percent of UV light. Prescription lenses will not necessarily block UV light, and for that matter, will not provide ANSI Z87-level impact protection unless they are expressly marked with a “Z87+” on the lens. Ultraviolet radiation is not significantly reduced by cloud cover. UV protection is recommended for outside workers even on overcast days.

Safety glasses come in all kinds of lens presentations that benefit outdoor users. Many outdoor workers find polarized lenses most effective in filtering out glare and adding definition. Mirrored lenses also prevent excessive light from causing fatigue and eye strain.

No Comments