12 Feb Glove Risks: Cuts

Of all the mechanical risks workers face, perhaps the most consequential is cut protection. If the task involves working around knives and saws, or sharp edges as with glass or metalworking, cut protection is extremely important.

Thankfully, cut resistance technology has evolved tremendously in the last 20 years, and there are many gloves available with very good cut resistance that are also comfortable and affordable. The improvement in cut protection prompted a revamp of testing standards in both the U.S. and Europe in 2016.

The ASTM F2992-15 testing method for rating cut resistance renders test results in a scale from A1 to A9, and this is the test method adopted in the U.S. performance standard. If the cut resistance information for a glove fails to show an “A” in front of the number of the cut rating, then the cut rating of the glove is either derived through a foreign test method or is possibly counterfeit. Either way, it should be disregarded.

Understanding the methodology of the ANSI test method is useful in comparing its relevance to the scenarios faced in your real world.

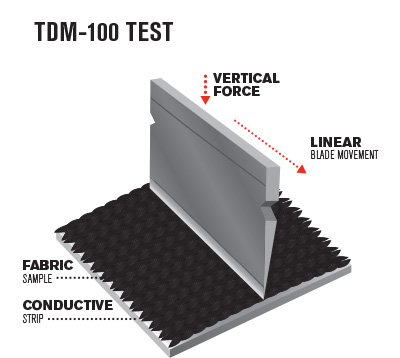

In the simplest terms, the test consists of passing a sharp blade (think: box cutter) across a swatch from the glove with increasing weight applied until the swatch is cut through. The blade and swatch are replaced for each pass to avoid dulling the blade or weakening the swatch and affecting the results.

The weight required to make the cut is recorded, and that number is used to derive the final score. The table below shows how the weight corresponds to the published rating:

Weight loads in grams required to cut through glove material

| A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 |

| ≥ 200 | ≥ 500 | ≥ 1,000 | ≥ 1,500 | ≥ 2,200 | ≥ 3,000 | ≥ 4,000 | ≥ 5,000 | ≥ 6,000 |

If your work involves opening boxes with a box cutter for example, the above test replicates this activity exactly. If your work involves cutting with shears, that’s different enough from the test method that you may wish to perform your own informal testing to see which glove is more resistant to that type of risk.

Another point worth remembering is that the published rating is based on testing of the palm of the glove. The back of the glove may have a different cut resistance value which the rating will not reveal.

A glove’s resistance to cut lies primarily in the composition of the liner or shell, and the palm coating has less influence over the cut properties. The uncoated back of the glove will likely have similar cut resistance to the coated front. However, there may be features of certain gloves that differ in cut resistance from the front to the back of the glove. If your work environment includes cutting risks to the back of the hand, you should examine whether the gloves you are using offer adequate protection to that part of the glove.

You can watch a video version of this topic HERE.

No Comments