05 Feb Glove risks: Abrasion

PART 2 OF A SERIES

While cut protection is important to protect your hands from accidental contact with a sharp blade, the abrasive wear that a glove experiences is anything but accidental. Handling rough materials or even a shovel handle or rope, your glove absorbs the friction and abrasion to protect your hands from blisters or worse.

The glove in the photograph was in use at a pallet manufacturing facility for less than a day of service. The low cost of these gloves does not translate into good value if they must be replaced before the end of the shift. It would be better to spend more on a glove with a higher abrasion resistance. If the glove can last 3 days instead of 5 hours, it can cost a lot more and still be a better value.

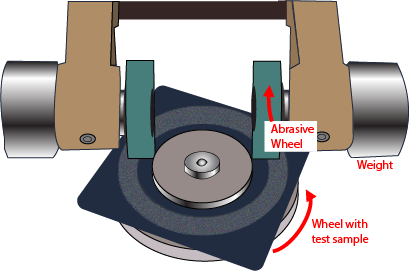

The ANSI test for abrasion is conducted on a swatch taken from the palm of the glove. The swatch spins like a phonograph record with two abrasive wheels riding on top with a weighted load for as many cycles as it takes for the abrasive material to wear through the glove. The abrasive wheels are off-center to the turntable, so they scuff the glove material as it rotates. If the test sample survives 1,000 cycles without wearing through, then the test is restarted with a fresh sample and double the weight load. The number of cycles to failure determines the rating:

Cycles required to wear through material:

| 0 | 1 | 2 | 3 | 4 | 5 | 6 |

| < 100 | ≥ 100 | ≥ 500 | ≥ 1,000 | ≥ 3,000 | ≥ 10,000 | ≥ 20,000 |

| Load = 500 g. | Load = 500 g. | Load = 500 g. | Load = 500 g. | Load = 1,000 g. | Load = 1,000 g. | Load = 1,000 g. |

As you can see from the photo at the top of this post, abrasion wear takes place where the stress is the greatest. In the case of this pallet worker, the highest stress areas are the thumb and middle finger.

This is something you will want to bear in mind knowing that the glove’s abrasion rating is measured using sample swatches cut from the palm. In cases where the highest wear areas don’t have the same composition as the glove’s palm, you will have to do your own evaluation about the suitability of that glove.

Unlike cut resistance, resistance to abrasion is heavily influenced by the coatings applied to the glove, which in most knit gloves is limited to the palm and front side of fingers. Many gloves are equipped with a reinforced thumb crotch, which is going to make a big difference for those who do a lot of shoveling or gripping of rope or cable. If that describes your situation, then a glove with thumb crotch reinforcement is going to perform much better than the same glove without that feature even though they will both show the same abrasion rating. If somehow the back of the glove would be subjected to abrasion in your work situation, then you would also need to wear test a few different kinds of gloves to find the one best suited to that application.

Click HERE for a video version of this content.

Glove risk series: Abrasion – HUB's Monday Morning Minute

Posted at 09:00h, 05 February[…] HERE for more information about abrasion […]